5000-10000L/H Big capacity disc separator for edible oil washing

Company Overview

Yixing Huading Machinery Co.,Ltd, is one of the market leaders in

the field of centrifugal separation technology in China.

The company has over 60 years experience in the design and

manufacturing.

Why Choose Us

1. 60+ years experience: HUADING has been manufacturing centrifuges since 1954.

2. 40000+ installations: HUADING separators are widely used in more than 50

countries/regions.

3. Innovation: More than 100 models are created to apply boardly in many fields.

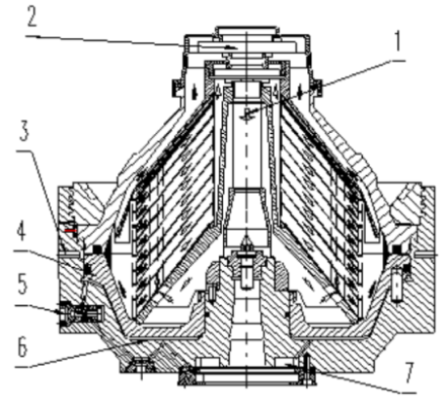

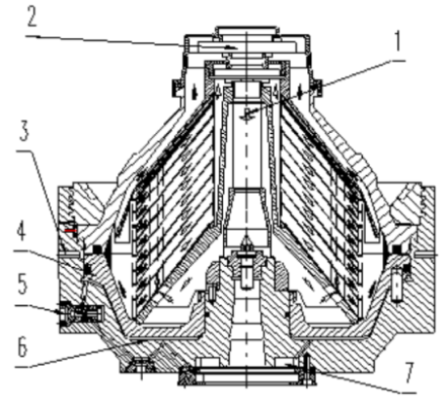

Working principle

1. Feeding pipe

2.Centripetal pump

3. Discharge port

4. Sliding piston

5. Small piston

6. Sliding piston chamber

7. Water room

After starting and reaches the full speed, the operating water 7

gets into the sealed chamber 6 to make

the piston 4 rise, close the outlet 3. Then the material to be separated is fed into the bowl from pipe 1.

Due to the centrifugal force, the impurities gather on the

periphery of the bowl. When at presentintervals,

the operating water 7 flows into open chamber 5 and forces the

sliding piston to drop down, open the outlet 3,

the impurities is discharged outside the bowl from outlet 3 and

outside the machine by impurities collection set;

at the same time, the light phase gather in the center of the bowl,

and is discharged outside the machine by

centripetal pump 2, heavy phase was introduced to centripetal pump

room via disc gland,and discharged out

by centripetal pump, finish one cycle, operating water 7 enter into

sealing chamber 6, raise up piston 4, ejection

port 3 closed...cycle in this way.

Manufacturing standard

| 1. JB/T20139-2011 | Centrifugal machinery requirements |

| 2. JB/T8051-2008 | Specification for strength calculation of centrifuge bowl |

| 3. GB19815-2005 | Safety requirements for centrifuges |

| 4. JB/T6418-92 | Centrifugal machinery - determination of cleanliness |

| 5. JB/T7214-94 | General technical specification for centrifugal machinery coating |

Main parts

Manufacturing