Advantages

1.) High speed, stable operation, all import and export systems are

sealed, noise is low, and separation effect is good.

2.) The professionally designed centripetal pump system has stable

output pressure, large adjustment range and convenient operation.

3.) The drum has a special structure, which has a large processing

capacity and good degreasing and clarifying effect.

4.) Professionally designed automatic control cabinet, can observe

the vibration value of the equipment at any time.

Two Operations Method

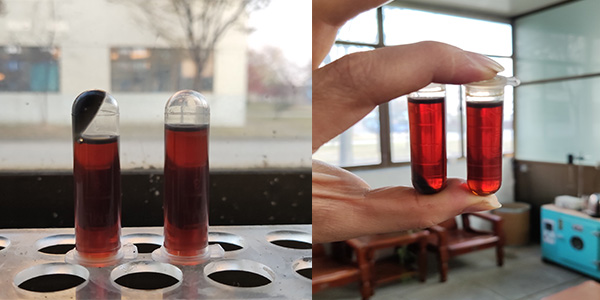

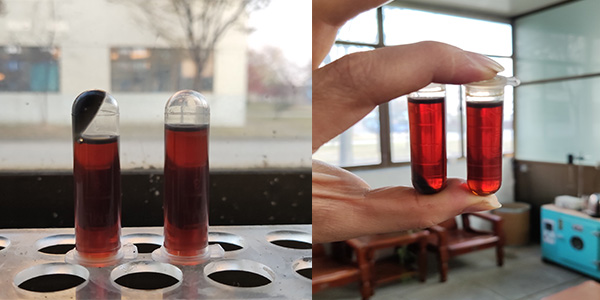

1. Liquid solid separation (i.e. separation of bottom concentration

suspension), which is called clarification operation, that is

two-phase separation.

2. Liquid-liquid separation (or liquid-liquid-solid) separation

(i.e., the separation of emulsion) is called separation operation,

that is three-phase separation.

Product description

HUADING MISD series disc stack separator used for the fuel oil

treatment, it can be used for the liquid purification and the

separation of liquid mixtures. The feed enter the rotary bowl after

going through the inlet and are clarified, purified or separated in

the disc system device.

According to the situation of the feeding mixtures of oil water,

automatic residue discharging separator and flushing separator is

alternative. The automatic residue discharging separator mainly

used for the separation of the feeding liquid with a high solid

content, it have the function of automatic residue discharging, no

need to disassemble the equipment very often to clean the

equipment. The flushing separator has the solid retaining type

bowl, it mainly used to treat the liquid with the solid content low

of 0.5%, the solid substances after separation will accumulate in

the residue area for manual removal

Main features

- Easy to clean and easy to maintain

- Full-automatic vibration detector can monitor the vibration

strength value of the centripetal pump at any time.

- Include automatically alarm

- With PLC control and screen touch operation

- Running in high speed, high g-force, operating stability, low noise

- Stability outlet pressure, large regulating sphere and operating

easily.

- Self-discharging , self-cleaning

Specification

| Product | 3phase disc stack separator |

| Model | MISD |

| Discharge type | Automatic/ manual |

| Automation degree | High |

| Material | Food grade stainless steel |

| Motor power | 5.5-37KW |

| Motor brand | ABB |

| Frequency | ABB |

| Bearing | SKF/FAG |

Company introduction

Huading Separator has been at the forefront in the field of

centrifugal separation technology for more than 60 years,

established in 1954, is the leader in mechanical separating

technology in China. The machines produced by Huading Separator are

used in a wide range of areas – in the beverage and dairy

industries, in recovering and processing oils and fats, as well as

in chemicals, pharmaceuticals, biotechnology and starch technology.

Other applications include marine engineering, energy, oil fields,

water treatment, such as waste water treatment, sludge dewatering,

etc

FAQ

1. Who you are?

Huading Machinery are separators and decanters manufacturer from

1954, we have more than 60 years experience in the design and

manufacturing of centrifugal separation equipment. Huading

separators and decanters are widely applied in industry of food,

beverage,pharmaceutical.chemical,marine,oilfield,energy,mining,mechanical

engineering and waste water treatment etc.

2. How do you guarantee the quality?

We are a professional manufacturer with experience of more than 60

years. We have the most advanced equipment and first-class workers.

Each of our processing procedures is strictly inspected and has the

test report. We also accept FAT testing from customers.

3. How long is the warranty period?

One year after the machine arrives customer site

4. Do you have technicians for installation, commissioning and

training?

After-sales service is available, we can send our technicians to

customer site for installation,commissioning and training, also can

guide online through video

5. What's the payment terms you can accept?

Generally T/T, L/C at sight